Our History

Generalities:

Rulmenti S.A., Barlad is a bearing manufacturing company located in Romania. The main shareholder is BERA Holding from Turkey. The company acts with approximately 1400 employees. Main activities are design, production, sales and service of different types of bearings.

Mission

To develop and implement strategies for global bearings solutions based on:

• Enhancing customer benefit using our high quality products and services;

• Promoting creativity and applying intellectual capital effectively;

• Building business partner confidence and internal teamwork performance;

• Attaining excellence through a strong organizational culture.

Vision

• Achieving recognition as a first class bearings producer and solution provider into bearings world market

Basic Values

• Skills and proficiency;

• Quality of delivered products and services;

• Knowledge and ideas sharing;

• Focus on customer satisfaction;

• Talent and creativity development of our people;

• Leadership and teamwork;

• Respect individuality and opinions;

• Sincere and fair in all businesses;

• Social responsibility.

We assure for our employees trainings with internal or external trainers in order to improve continuously our team members competences.

Our History

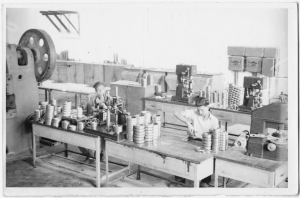

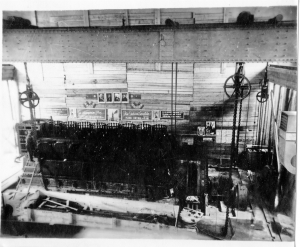

In 1953, the company started to produce bearings. A continuous improvement process was developed through the actual design, production and control facilities. Numerous changes were implemented in order to raise the life expectancy, loading capacity and operating precision of the bearings.

We include the respect for clients and the satisfaction of their needs among our fundamental principles. Therefore we tried to respond better to the market requirements by offering, besides the bearings with standardized shapes and sizes, a large range of non-standardized bearings, specific to various utilization.

Tooling department is a competent business partner ready to offer advice, to help and solve problems. We have our own production capacity and can process parts and pieces under customer’s orders.

RULMENTI S.A. BARLAD is a worldwide supplier of bearings and services in the rolling bearing business. The Company is among the biggest producers of rolling bearings from Europe and is known in the world market more than 65 years.

Today RULMENTI SA produces and distributes under URB brand a full range of bearings including: Radial Ball Bearings, Cylindrical Roller Bearings, Spherical Roller Bearings, Thrust Ball Bearings, Thrust Cylindrical Roller Bearings, Tapered Roller Bearings all well-known for their precision and reliability. All bearings are produced in accordance with the standards of International Organization of Standardization (ISO) and DIN standards.

RULMENTI SA is close to the customers through the wide distributor network in more than 40 countries, e.g. Romania, Germany, UK, Italy, Benelux, France, Spain, Ireland, Greece, Poland, Bulgaria, Serbia, Ukraine, Turkey, USA, South Africa, Brazil, Egypt, India, Korea, Taiwan, Thailand, Singapore, Vietnam, U.A.E. and other country.

The following steps describe the evolution of the company in the bearing production and bearing market:

Latest news

Latest news